Last week we looked at some of the interesting parts of the apple picking process. This time around, we are going to be looking at the banana process and how we manage to get yellow bananas all year long.

Bananas are picked green, unlike apples which growers wait to ripen before plucking off of the trees. The biggest reason for this is bananas release naturally-occuring ethylene gas to stimulate the ripening process. If the plump bananas were picked in a more yellow state, they would be inedible by the time they got to stores.

Regardless of when they are picked, bananas release ethylene. This creates a sort of race against the clock for the fruits. Bananas need to be kept cold and ventilated, otherwise the gas will begin to turn the bananas.

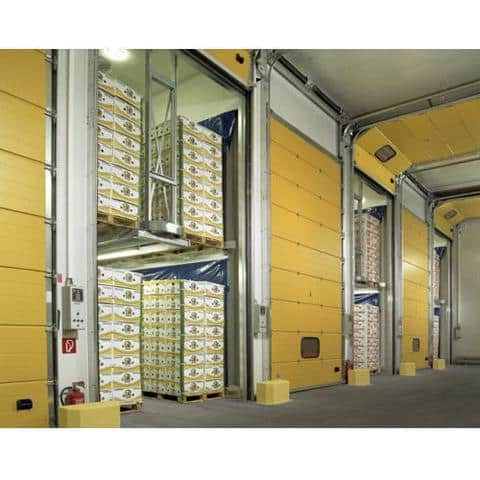

Bananas then get to the distributor where they are put into storage facilities called “banana elevators.” Up to this point in the process, we’ve been trying to avoid ethylene to keep the bananas green. Once they’re in the elevators, they are intentionally exposed to an ethylene treatment to rapidly; and safely, ripen up the bananas.

Once they’ve reached a desired ripeness they are sent out from the distributor to be enjoyed by the masses. Bananas are best stored between 56 and 58 degrees. At ThirdLeaf, we have a specific cooler set to that range so the bananas can be as close to perfect as possible.

We can bring some of these bananas to your business for a free trial if you would like. We supply businesses all over the Puget Sound with fruit and healthy snacks. Click here to set up your free trial today!